Belt Cleaner

CERAMIC BELT CLEANER- A PATENT DESIGN

Tech Products, Singapore develop ceramic belt Cleaner with support of Japanese Technical Support (A Patent Design Belt Cleaner). Our Belt Cleaner is the newest type of belt scraper, Totally different from the conventional structures. For remove tailings on the surface of the encrusted belts carrying material. Our, belt cleaner technology systems helps bulk materials handling facilities accomplish their goals for safety, cleanliness, environmental compliance and operating efficiency.

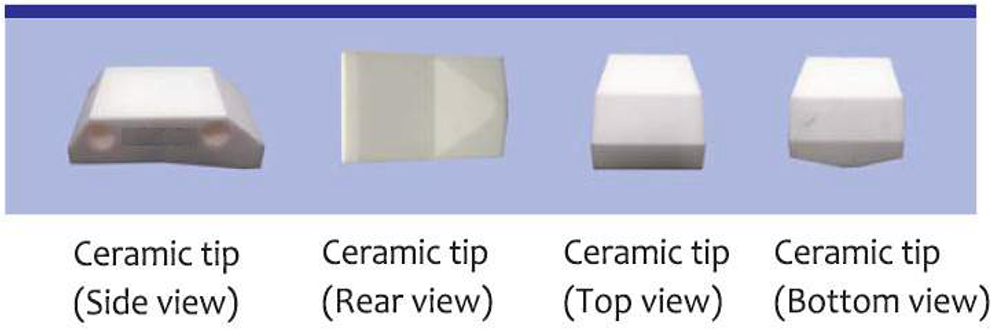

Structure of BeltCleaner’s Ceramic Components:

Our developed engineered components will improve performance and reduce spillage and airborne dust. And engineered flow transfer chutes help material handling operations achieve new standards of excellence

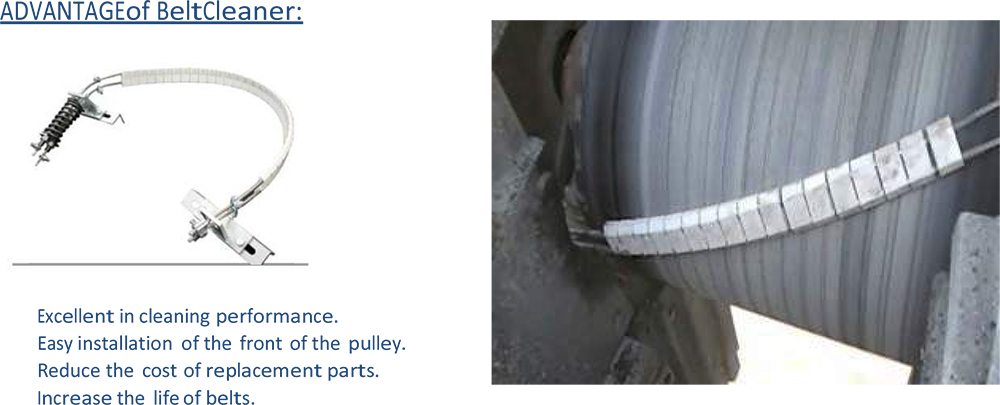

Our belt cleaner is positioned in the front part of the head pulley. The scraper has developed to act as efficient system for cleaning of waste materials and aggregates. Waste sent to the pipeline or chute means more cleaning along the belt and reducing overall costs. We have developed to clean with maximum efficiency to the waste materials.e

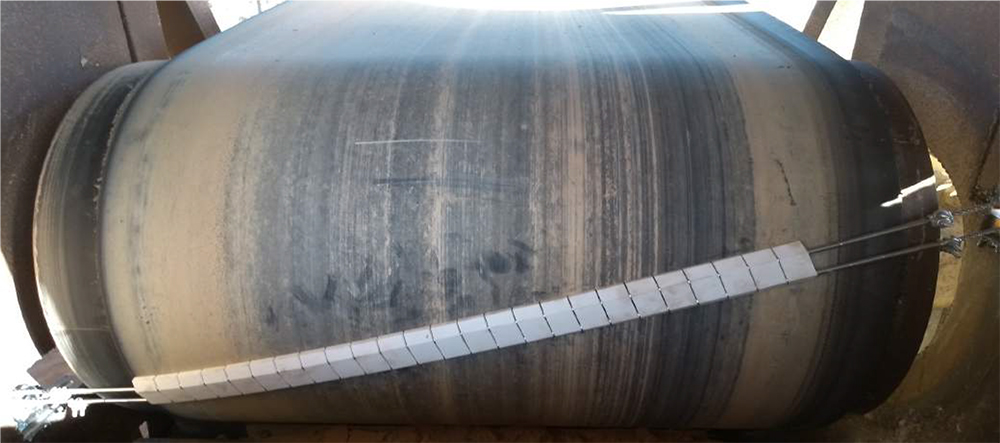

There are two installation methods for Ceramic Belt Cleaner depending on the pulley width and diameter. Normally, the

The belt cleaner reduce costs and maintenance, have long life, high performance, easily to install and most importantly no need to install more than one.

The efficiency of the cleaning is superior by the persistence of the power of abrasion from the chips. The structure of ceramic and metal is resistantin the face of low and high temperature, otherwise it is installation is extremely easy.

Belt Cleaner’s Holder:

Newly improved spring tensioned and fixed side holders are shown in above photos at the upper left and right sides respectively. With the new holders, the belt cleaner becomes easier to install than conventional belt cleaners and its wire becomes adjustable individually. In addition, the ceramic tips can contact with a conveyor belt more closely to improve the cleaning efficiency.

The belt cleaning is installed from the axis of the conveyor belt, until bottom of the belt apart, demonstrating the efficiency of cleaning.