Forged Steel Back up Rolls

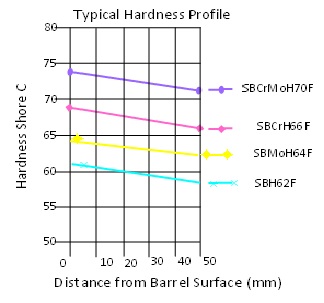

The grades have 3% and 5% Chromium together with Molybdenum and Vanadium, differentially hardened to achieve bainitic to martensitic shell with spheriodized pearlitic core.

Chodan Sazan produces forged steel back up rolls for hot and cold strip mills. These rolls are used in continuous, Semi Continuous and Steckel Hot Strip Mills, also Tandem Cold Strip Mill and Temper Mills.

SB H 62F- Tempered Martensite(x200)

| Mechanical Properties | Barrel | Neck |

|---|---|---|

| U.T.S (N/mm²) | 1300-1800 | 700-1300 |

| Yield Strength (N/mm²) | 1200-1500 | 630-1050 |

| Bending Strength (N/mm²) | 2500-3000 | 1000-1500 |

| Elongation (%) | 6-12 | 12-22 |

| Roll Grade | Barrels Hardness (ShC) | C (%) | Si (%) | Mn (%) | Cr (%) | Mo (%) | V (%) |

|---|---|---|---|---|---|---|---|

| SB H 62 F | 62 | 0.52-0.62 | 0.2-0.5 | 0.3-0.7 | 3.0-3.3 | 0.3-0.6 | 0.1-0.3 |

| SB H 64 F | 64 | 0.52-0.62 | 0.2-0.5 | 0.3-0.7 | 3.0-3.3 | 0.3-0.6 | 0.1-0.3 |

| SB Mo H 64 F | 64 | 0.55-0.65 | 0.2-0.5 | 0.3-0.7 | 3.0-3.3 | 0.6-1.0 | 0.1-0.3 |

| SB Mo H 66 F | 66 | 0.55-0.65 | 0.2-0.5 | 0.3-0.7 | 3.0-3.3 | 0.6-1.0 | 0.1-0.3 |

| SB Cr H 66 F | 66 | 0.45-0.55 | 0.2-0.5 | 0.3-0.7 | 5.0-5.3 | 0.3-0.6 | 0.1-0.3 |

| SB Cr H 68 F | 68 | 0.45-0.55 | 0.2-0.5 | 0.3-0.7 | 5.0-5.3 | 0.3-0.6 | 0.1-0.3 |

| SB Cr Mo H 70 F | 70 | 0.5-0.6 | 0.2-0.5 | 0.3-0.7 | 5.0-5.3 | 0.6-1.0 | 0.1-0.3 |

| SB Cr Mo H 72 F | 72 | 0.5-0.6 | 0.2-0.5 | 0.3-0.7 | 5.0-5.3 | 0.6-1.0 | 0.1-0.3 |